What is well logging?

As a well is drilled, core samples, drilling fluid, well logs, and test results are carefully analyzed in order to understand as much as possible about the environment surrounding the wellbore. Well logs are the primary means of determining formation depth and what type is it, and many other critical information. A log is a record of information about the geological formations that have been drilled through, it is also referred to as borehole logging.

What well logs show?

Well logs show everything about a borehole. They examine and record data relating to:

- Rock Composition: The type of elements and minerals present. Common strata types include limestone, sandstone and shale. A log determines what rocks line the borehole.

- Rock Characteristics: For instance, the presence of liquid. Fluids in rock fall under the categories of permeability and porosity.

- Rock integrity: The strength of rocks regarding fracturing. Analysis of structural liabilities and risk of cave-ins.

- Liquid Presence: Type of fluids in the borehole. Their salinity, pressure and saturation.

- Borehole Factors: Shape, size, angulations and trajectory of the borehole. How the engineering aspects relate to the previous factors, whether any problem will arise.

- Hydrocarbon Presence: In addition to valuable minerals, hydrocarbons such as oil and gas represent another thing logs display.

Logging procedure and its methods

Sometimes the logging tools are lowered into the well at regular intervals to collect data (wireline logging), and sometimes the logging tools are incorporated into the drilling tool (logging while drilling).

Wireline logging

Onshore, wireline logging is done from a logging truck with specialized equipment, sometimes referred to as a “mobile laboratory”. Offshore, the same equipment is installed in a small cabin left permanently on the rig. To run wireline logs, the hole is cleaned and stabilized and the drilling equipment extracted, then the logging tools attached to the logging cable and lowered into the hole to its maximum drilled depth. Most logs are run while pulling the tool up from the bottom of the hole, as the device rises upward, it continuously records a constant stream of data relating to the borehole. The information is digitally cataloged and represented in a standardized log spreadsheet. Because rig time is expensive and holes must be logged immediately, modern logging tools are combined and multi-function

Logging while drilling (LWD)

Logging While Drilling (LWD) technique was introduced to provide similar information to wireline logging. However, as opposed to wireline logging where tool string is lowered into the well at the end of a wireline cable after the hole is drilled, the sensors in LWD are integrated into drill collars (DC’s) and the measurements are made while the well is being drilled. LWD tools provide deviation and logging options in high-angle wells. However, their greatest advantage is the real time data acquisition at surface which saves considerable logging time to the companies to allow them make important field development decisions much earlier.

Some of the advantages LWD tools offer, which justifies their additional costs and complications for drilling, include the following:

- Obtaining pre-invasion formation profile and data prior to the hole washing out, or if there is a risk of losing the hole is obtained.

- Real time data is obtained for steering a well and changing direction in order to optimize its performance.

- Data is obtained in situations where wireline acquisition is difficult especially in horizontal wells.

No doubt that LWD has excelled wireline in operation over the years and will continue to do so. Ideally, wireline logging would be replaced because it uses several days of rig time.

Well logging overview

Mud logging

Mud Log refers to the drilling fluid or mud, used to provide buoyancy to the drill, as well as remove cuttings from the well. Information from mud log supplements logs of nearby wells to determine the commercial ability of a well. Additionally, mud log monitors the wellbore by analyzing the cuttings from drilling fluid that circulated to the surface, this also helps prevent blowouts when drilling bit contacts with potential high pressure zone.

Measurement while drilling (MWD)

Most MWD systems were based on mud telemetry, where pressure variations in the mud pulse created by the MWD tools were sensed by a computer on surface. MWD systems are usually used in directional drilling, since it can provide information on inclination and trajectory of the wellbore in real time.

Types of well logs

With well logs serving so many purposes, there are various types of well logs that suit each purpose.

Here are some of the types of well logs that are commonly being used.

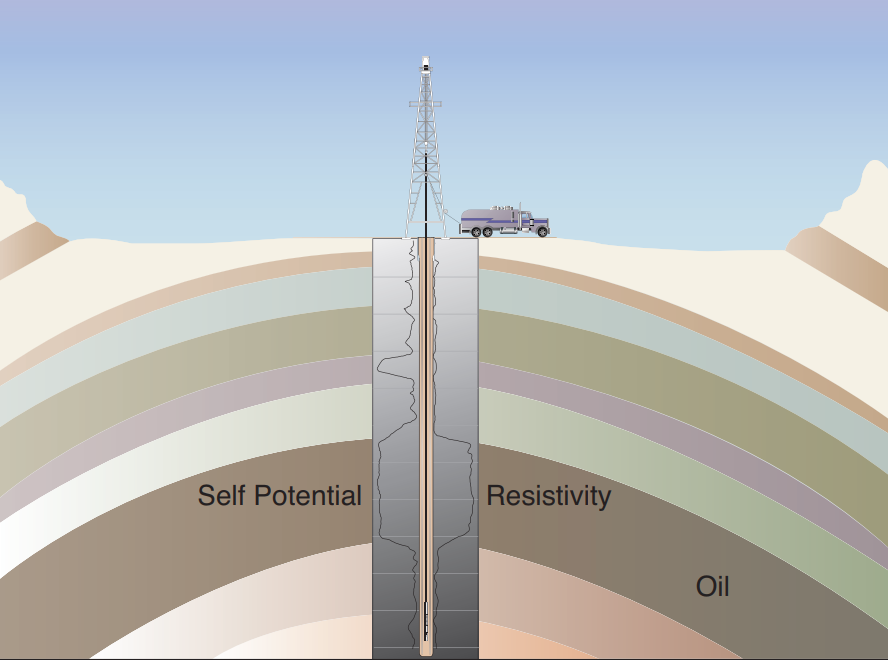

- Electrical resistivity well logs tell you how hard it is for an electric current to pass through a formation. This is also an indication of whether the water in the potential well is fresh or salty. (Salt water conducts more electricity making it easier for the electric current to pass through.)

- Acoustic or sonic well logs tell you how easy it is for sound waves to travel through the formation. This is useful to see if water is present in the formation.

- Gamma ray or radioactivity well logs let you know how much shale is present in the formation, since shales tend to have higher level of gamma radiation than other types of rock.

- Induction well logs measure the conductivity of the wellbore. Formations that contain oil are less conductive of electricity than water-bearing formations. When compared with porosity measurements, the conductivity can aid in determining where oil zones occur.

- Spontaneous potential (SP) well logs record the weak currents that flow naturally in the rock next to the wellbore. The curve may be used to determine the boundaries and thickness of the permeable rock formation.

- Nuclear Magnetic Resonance (NMR) logs uses a neutron source to record the presence of hydrogen in a borehole. Hydrogen atoms in boreholes commonly appear as water, or the hydrocarbons oil and gas. The levels of measured hydrogen help predict the presence of these elements.

- Calliper well log provides a continuous measurement of physical shape of a borehole along its depth. Data from this log helps determine the strength of the borehole in relation to the rock. This helps prevent the borehole from collapsing or developing other structural problems.

Reading a well log:

The well log includes the header, which provides specific information about the well, such as the operating company, well information and type of log run; as well as the main log section, or the graph. The graph charts vertically the depth reached, and the horizontal scale is the measurement scale, which can be represented linearly and/or by logarithms.

Inserts are found throughout the graph at each major section of the log, identifying each curve. Curves on the log, also called traces, readings or measurements, can be represented by solid, long-dashed, short-dashed or dotted lines to decipher between the different measurements represented on the log.

The final part of the log includes the tool calibrations for before and after the log was conducted, ensuring that the log is accurate.

Data interpretation

The main objective of well logging is to obtain the properties of the rocks which are potential sources of hydrocarbons. Hence, the logs are used to determine specifically the lithology of formation, porosity, fluid content and saturation. These information will give geologists the insight of the productive formation for further development of the well. We will discuss the procedure and principles, on which interpretation of logging data based, and how logging data can give us every information mentioned above in another chapter of this series. See the link below:

http://i2g.cloud/general-procedure-to-interpret-the-logs/